Deburring

Totem Burrs are manufactured using high quality carbide on latest world class CNC machines with auto loaders to guarantee the best accuracy, precision and repeatability. Totem burrs are manufactured using the best quality of ram material. The EN-24 shanks used are precision turned and ground to ensure the least possible run out.We offer Tin and TiCN coating which has many benefits like Increase tool life, reduced cutting forces, improved machinability and better chip evacuation. We offer burrs in many shapes as follows.

Burr Case Set:

- Made with optimum Cobalt content, the carbide has a long and operative working life

- With a variety of shapes and sizes, the wooden cased sets offer excellent portability with minimum hassles of storage

- Made of high quality heat-treated tungsten carbide, ensuring its hardness can reach to HRC70

- Ideal for cleaning up welds, grinding weld beads, shaping parts, smoothing rough castings, or porting cylinder heads. Vast application in body shops, fabrication shops, brake shops, industrial shops, die manufacturers, and more

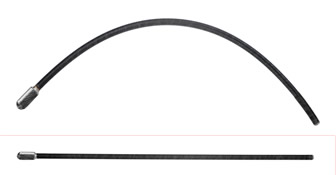

Flexible Carbide Burrs: Flexible Shaft Carbide burs is for Specialty cleaning of impeller, Pump housings, and all Castings, Excellent for the cleaning of burnt sand, welding, fins, and inner Pipe cleaning, and all other blending operations.

- Metric size flexible shank carbide burs are available upon customer’s request

- Available in 6”, 8”, 10”, & 12” length and all shapes. For special length and shapes, please send us email – [email protected]

- Our rotary burrs are brazed by the advanced welding equipment automatically. The cutters are made by the modern CNC grinding machines.

- Flexible shank carbide burrs manufactured to your drawings to meet your demands of particular stock removal.

- TOTEM flexible shank carbide burs can be coated with TiN, TiCN, TiALN

- Best Suited to castings in areas that are difficult to reach with standards.

- Focus on Turbine blade assemblies, Pump Casings, Pump Impellers.

Types of Shape

Types of Cut

Standard Cut (Single Cut): This flute structure is designed for superior material removal and general purpose application. These can be used on Steel, Steel alloys, Cast Iron, Stainless Steel, Hard Bronze and Copper.

Supreme Cut (Double Cut/ Cross Cut): This burr allows for efficient stock removal in the harder materials. Its design reduces tool chatter and breaks the chip into granular shapes. These smaller chips also help to eliminate loading on the flutes. This design helps to have better control on the burr and grinder.

Deluxe Cut (Diamond Cut): This design of tool is like triangular style of point, which produces extremely small chips (powder like chips). The cut eliminated pulling action of the ,ain cut and offers the operator good control over the tool and produces excellent finish. Effective in heat treated steels and tough alloy steels.

Aluma Cut: Designed for rapid stock removal on Non ferrous material. Recommended to work on Aluminium, Zinc alloy, Hand rubber and wood.

Coarse Cut: Designed for hard aluminium alloys with an Si-content greater than 12 % and non-ferrous metals.